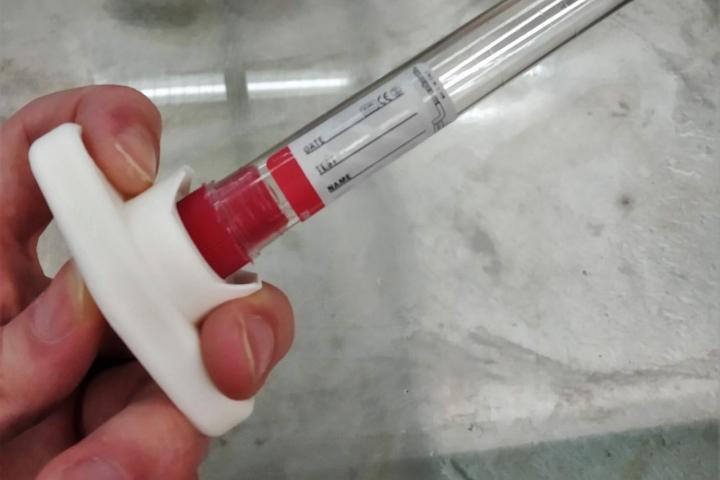

After a short discussion with the doctor, Bc. Jiří Kubík got interested in the preposal, a student of the master's program Open Informatics, who, in addition to his studies, works as a robotics researcher at the Center for Artificial Intelligence, FEE CTU. When describing the problematic manual opening of the test tubes, he immediately remembered the PET bottle opener, which he remembered from his grandmother. The aid that many of us have at home even today makes it easier to turn the lid without the need for much force. Kubík used the same principle when designing the test tube opener. In contrast to the classic PET bottle opener, it also has protective wings that prevent contact between the glove and the contaminated interior of the lid, and a sliding pin for easier handling of the lid when unscrewing it. The author also consulted the final form of the design with a colleague from the laboratory of Bc. Jakub Sláma from FEE CTU and Mgr. Adéla Přibylová from the Faculty of Natural Sciences, Charles University, with whom she collaborates on automation of testing for the Motol University Hospital.

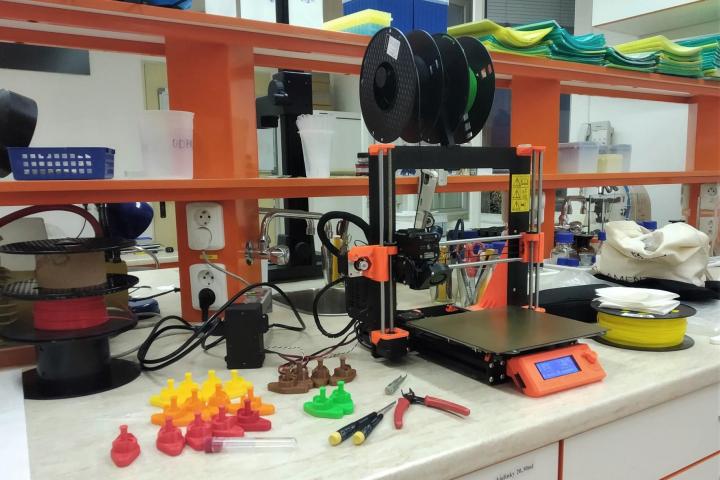

The device is completely manufactured on a 3D printer, which enables fast and local production, low costs and immediate use in laboratories. Every day, Kubík is able to produce 20-30 openers, on his own 3D printer and a printer borrowed from CIIRC CTU. At present, they are already used by seven laboratories, to which they were delivered on request via a network of ambulances transporting samples throughout the country. However, the opener can be printed by anyone who owns a 3D printer. Kubík placed the design on the open source platform Thingiverse, from where anyone can download it for free. Other laboratories throughout the Czech Republic were informed about this through the State Medical Institute of the Czech Republic.

The opener design for 3D printing can be downloaded here: https://www.thingiverse.com/thing:4272124