The idea of producing space-saving equipment that will produce heat and electricity with the possibility of independence from other energy sources was originally the basis of the dissertation thesis by Ing. Maščuch. After 10 years of research and development at the CTU University Center of Energy Efficient Buildings, the microelectric plant is fully operational and ready to run under different conditions. The power plant has a number of automated functions and is virtually maintenance-free.

"One of the main advantages of the microelectric power plant is that automation has reduced the need for operator presence to almost zero, as it is a self-sustaining system that is not dependent on the supply of electricity from the distribution network, and it is applauded by the fire department, which is so independent on the supply of electricity and heat from outside, as well as minimal emissions, which contributes to the improvement of the winter climate and air-pollution in the village, "said Mayor of Mikolajice Martin Krupa.

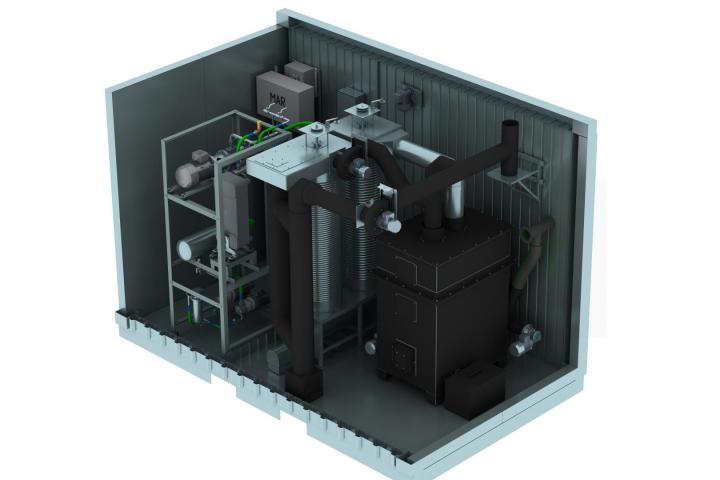

As a next step, the authors are going to launch small-scale production of the device that reaches 120 kW of thermal and 6 kW of electrical power. The reason for the development of a power plant with higher performance parameters is significantly better economic efficiency. Damgaard Consulting will introduce it on the market. According to Jakub Maščuch, the return on the whole investment corresponds to the life expectancy of the equipment at current energy prices. Compared with other boilers, the WAVE microelectric plant is the only device that covers its purchasing expenses during its lifetime thanks to the energy savings. Ultimately, users have pay for the heat only at the cost of the fuel.

The modern energy source with 120 kW heat output will find its application for example in guest houses, hotels, farmhouses, apartment buildings or wellness centers. The power plant can be modified to be absolutely independent of the distribution network and can therefore work virtually anywhere. This type of device can also become a very good technological foundation for expanding Smart Grids, power and communications networks to regulate power consumption and power generation in real time. Three years ago, specialist jury at the E.ON Energy Globe competition appreciated it with an award. E.ON also supported the project with 300,000 CZK and helped it to develop and increase media coverage.

The intention of installing WAVE in the village of Mikolajice was brought up by the start-up YOUNG4ENERGY, which helped the village with a comprehensive preparation of the entire project, including the necessary project documentation, official permits and subsidy management.

The following media reported about the WAVE: CT24.cz and 24.zpravy.com.